Wiring a detailed model car engine can transform a static display into a captivating miniature marvel. This guide will walk you through the process, covering essential techniques, tools, and tips to achieve a realistic and impressive outcome. Whether you’re a seasoned model builder or just starting out, understanding How To Wire Detail Model Car Engines can elevate your projects to the next level.

Planning Your Wiring Project

Before diving into the wiring process, careful planning is essential. Begin by researching your specific model car engine. Reference images and diagrams are invaluable resources for understanding the engine’s layout and wiring configuration. Identify the key components such as the distributor, spark plugs, coil, alternator, and battery. This initial research will provide a roadmap for your wiring project and prevent costly mistakes. Choose the correct scale wiring, available from various hobby suppliers, to ensure a realistic appearance.

Essential Tools and Materials

Having the right tools and materials will streamline the wiring process. Fine-tipped tweezers, wire strippers, and a soldering iron with a small tip are crucial for precise work. Heat shrink tubing is essential for insulating connections and adding a professional touch. A good quality adhesive, like cyanoacrylate (CA) glue, will secure wires in place. Lastly, a multimeter can be invaluable for troubleshooting any electrical issues.

Essential wiring tools for detailed model car engines

Essential wiring tools for detailed model car engines

Step-by-Step Wiring Guide

This section provides a detailed, step-by-step guide on how to wire detail model car engines.

-

Prepare the Wires: Cut the wires to the appropriate lengths, referencing your research materials. Carefully strip the insulation from the wire ends, exposing a small amount of bare wire for soldering.

-

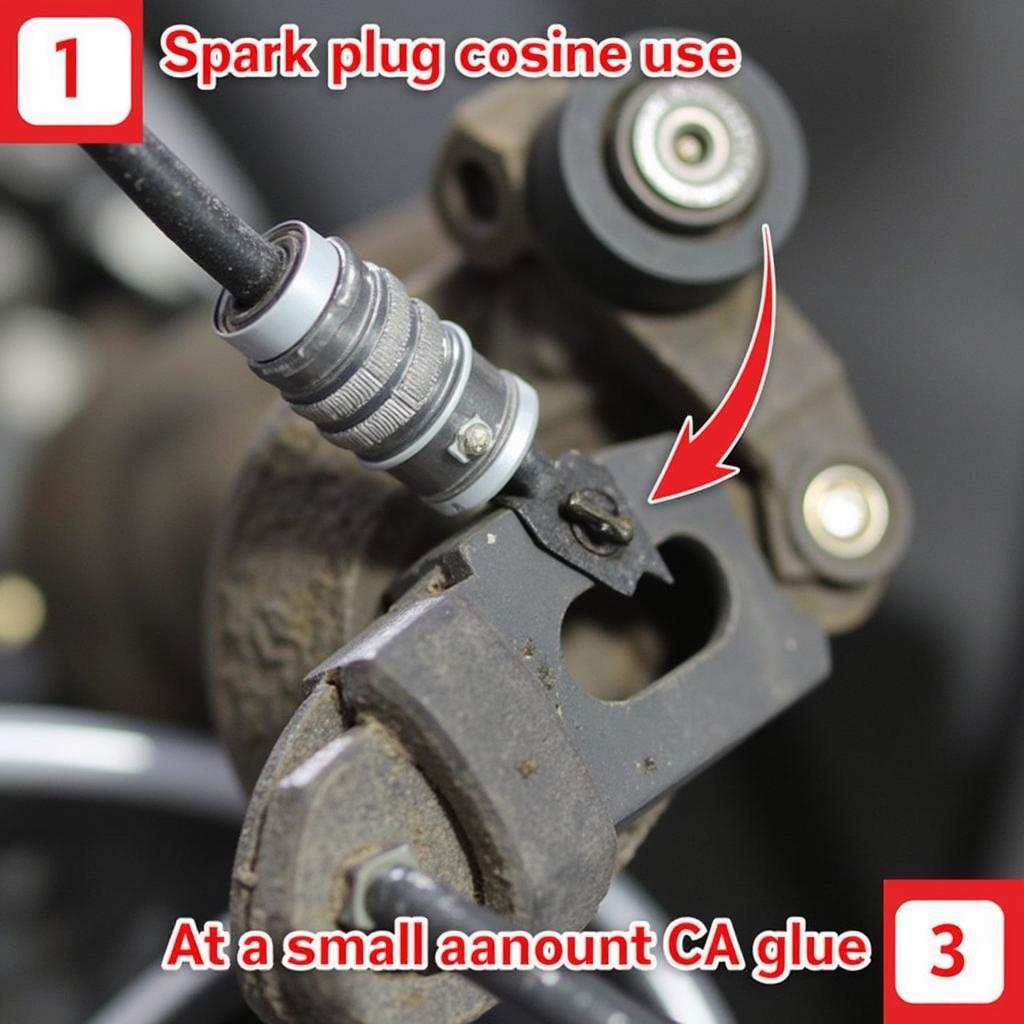

Connect the Spark Plugs: Attach the spark plug wires to the distributor cap, ensuring the correct firing order is followed. Use small amounts of CA glue to secure the connections and prevent accidental detachment.

-

Wire the Distributor: Connect the distributor to the coil using the appropriate wire. This connection is critical for the ignition system to function correctly. Use heat shrink tubing to insulate the connection.

-

Connect the Coil: Wire the coil to the positive terminal of the battery. This provides the necessary power for the ignition system.

-

Wiring the Alternator: Connect the alternator to the battery and the appropriate points on the engine block. This ensures that the electrical system is powered once the engine is running (in a functional model).

Connecting spark plug wires to the distributor cap in a model car engine.

Connecting spark plug wires to the distributor cap in a model car engine.

- Grounding the System: Connect the negative terminal of the battery to the engine block to complete the electrical circuit. This is an essential step for a functional electrical system.

Troubleshooting Tips

Occasionally, you might encounter challenges during the wiring process. If the engine doesn’t start (in a functional model), double-check all connections to ensure they are secure and correctly placed. A multimeter can help identify any breaks in the circuit. Refer to your research materials and diagrams to verify the wiring layout.

Adding Realistic Details

Once the basic wiring is complete, you can add realistic details to enhance the appearance. Use small cable ties or carefully placed drops of glue to mimic the way wires are bundled and routed in real car engines. Painting the wires to match the original engine’s wiring can further improve the realism.

Adding realistic wiring details to a model car engine.

Adding realistic wiring details to a model car engine.

Conclusion

Wiring detail model car engines can seem daunting initially, but by following this guide and practicing patience, you can achieve remarkable results. Remember to plan carefully, use the right tools, and take your time. With each project, your skills will improve, and you’ll be able to create increasingly intricate and realistic model engines.

FAQs

- What type of wire should I use for detailing model car engines?

- Where can I find scale wiring for my model car project?

- What is the best adhesive for securing the wires?

- How can I troubleshoot electrical issues in my wired model engine?

- What are some tips for adding realistic details to the wiring?

John Smith, a renowned model car builder with over 20 years of experience, emphasizes, “Accurate research and planning are the cornerstones of successful model engine wiring. Don’t rush the process, and always refer to your source material.”

Another expert, Sarah Johnson, a celebrated model maker known for her intricate detailing, adds, “Using the right tools, especially fine-tipped tweezers and a quality soldering iron, is essential for achieving clean and precise wiring.”

Need help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected]. We have a 24/7 customer support team.

Leave a Reply