Car Repair Ramp Detail Drawings are essential for any professional or DIY mechanic. Understanding the nuances of these drawings is crucial for safe and effective vehicle maintenance. Whether you’re building your own ramp or purchasing a pre-fabricated one, a detailed drawing provides the necessary blueprint for success.

Understanding the Importance of Car Repair Ramp Detail Drawings

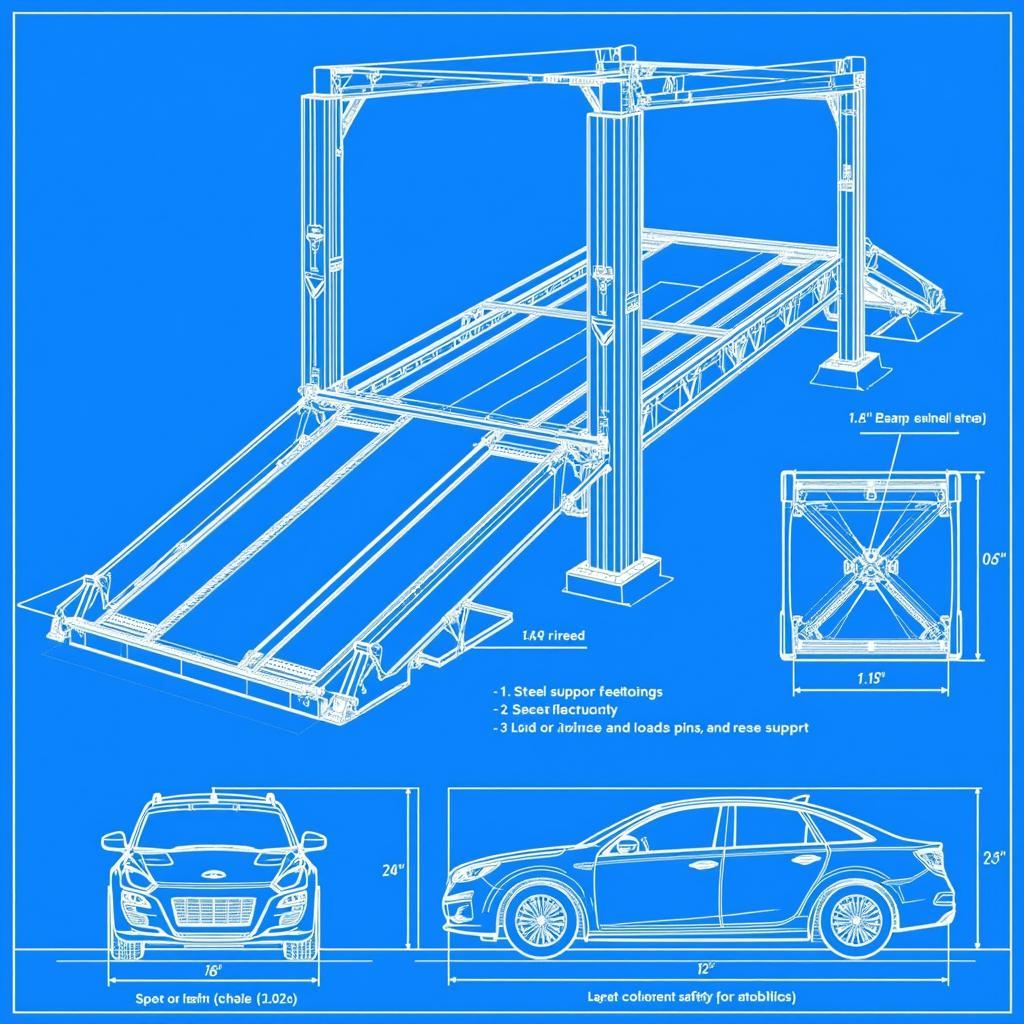

A car repair ramp detail drawing offers a precise visual representation of the ramp’s design, including dimensions, materials, and construction methods. This information is vital for several reasons:

- Safety: A well-designed ramp ensures the stability and safety of the vehicle during repairs. The drawing highlights critical safety features such as load capacity, angle of incline, and support structure.

- Functionality: The drawing specifies the ramp’s dimensions, allowing you to ensure it’s suitable for your vehicle’s size and weight. It also details features like ramps, wheel stops, and other functional elements.

- Construction: Whether you’re building your own ramp or hiring a professional, the detailed drawing serves as the primary construction guide. It provides precise measurements and material specifications, ensuring a sturdy and reliable structure.

- Compliance: A car repair ramp needs to meet specific safety standards. A detailed drawing helps ensure compliance with these regulations, minimizing potential liabilities.

Key Elements of a Car Repair Ramp Detail Drawing

A comprehensive car repair ramp detail drawing should include the following key elements:

- Overall Dimensions: Length, width, and height of the ramp.

- Angle of Incline: The slope of the ramp, crucial for safe vehicle ascent and descent.

- Load Capacity: The maximum weight the ramp can safely support.

- Material Specifications: The type and thickness of materials used for the ramp’s construction (e.g., steel, aluminum).

- Support Structure: Details of the ramp’s framework, including supports, bracing, and reinforcement.

- Wheel Stops: Design and placement of wheel stops to prevent the vehicle from rolling off the ramp.

- Safety Features: Any additional safety features, such as safety chains or locking mechanisms.

Different Types of Car Repair Ramps and Their Drawings

Different types of car repair ramps cater to various needs and vehicle types. The detail drawings will vary accordingly. Here are a few common types:

- Portable Ramps: These are lightweight and easily transportable, ideal for occasional use. Drawings typically focus on portability features and simpler construction.

- Stationary Ramps: These are permanently installed ramps, suitable for workshops and garages. Their drawings are more complex, highlighting structural integrity and load-bearing capacity.

- Hydraulic Ramps: These ramps use hydraulics to lift the vehicle, offering greater accessibility. Drawings for these ramps are more intricate, detailing the hydraulic system and safety mechanisms.

How to Interpret a Car Repair Ramp Detail Drawing

Interpreting a detail drawing correctly is vital for successful ramp construction or purchase. Here’s a step-by-step guide:

- Understand the Scale: The drawing will have a scale indicating the relationship between the drawing’s dimensions and the actual ramp size.

- Identify the Views: The drawing will typically include different views (top, side, front) to provide a complete picture of the ramp.

- Review the Dimensions: Carefully examine the dimensions of each component to understand the overall size and proportions.

- Analyze the Material Specifications: Note the materials specified for each part of the ramp, ensuring they meet your strength and durability requirements.

- Study the Support Structure: Understand how the ramp is supported and braced to ensure its stability.

Stationary Car Repair Ramp Blueprint

Stationary Car Repair Ramp Blueprint

Building Your Own Ramp Using a Detail Drawing

Building your own car repair ramp can be a cost-effective solution. However, it requires careful planning and execution.

- Choose the Right Drawing: Select a detail drawing that meets your specific needs and skill level.

- Gather the Materials: Procure the necessary materials according to the specifications in the drawing.

- Follow the Instructions: Adhere strictly to the dimensions and construction methods outlined in the drawing.

- Prioritize Safety: Ensure all safety features are incorporated correctly.

“A well-designed ramp is an investment in safety and efficiency,” says John Smith, Senior Automotive Engineer at Smith Automotive Solutions. “A comprehensive detail drawing is the foundation of a successful ramp project.”

Conclusion

Car repair ramp detail drawings are indispensable tools for anyone working with car ramps. Understanding these drawings is crucial for ensuring safety, functionality, and compliance. By following this guide, you can effectively interpret and utilize these drawings to build, purchase, or simply understand the mechanics of car repair ramps. Remember, a precise car repair ramp detail drawing is the key to a successful and safe car maintenance experience.

FAQ

- What is the standard angle of incline for a car repair ramp?

- What materials are commonly used in car repair ramp construction?

- How do I determine the appropriate load capacity for my car repair ramp?

- Where can I find reliable car repair ramp detail drawings?

- What are the key safety features to look for in a car repair ramp drawing?

- What are the different types of car repair ramps and their specific uses?

- How do I interpret the different views in a car repair ramp detail drawing?

Need further assistance? Contact us via WhatsApp: +1(641)206-8880, or Email: [email protected]. Our 24/7 customer support team is ready to help.

Leave a Reply