Maintaining the differential in your Mercedes-Benz W201 is crucial for its longevity and performance. One key aspect often overlooked is the pinion shaft friction, or more accurately, the pinion shaft preload. Getting this adjustment correct is vital to prevent premature wear and ensure smooth operation. This article will delve into why proper pinion shaft friction is important for your W201, focusing on the relationship between the pinion and crown wheel gears and the bearings that support them.

To understand pinion shaft friction, we first need to look at the components within the differential. The pinion gear and crown wheel are essential for transferring power from the driveshaft to the wheels. The teeth of these gears have specific sides known as the “drive” side and the “coast” side. The drive side is the face of the tooth that primarily engages during forward acceleration, bearing the brunt of the driving force. The coast side comes into play during deceleration or when the engine is not under load in the forward direction.

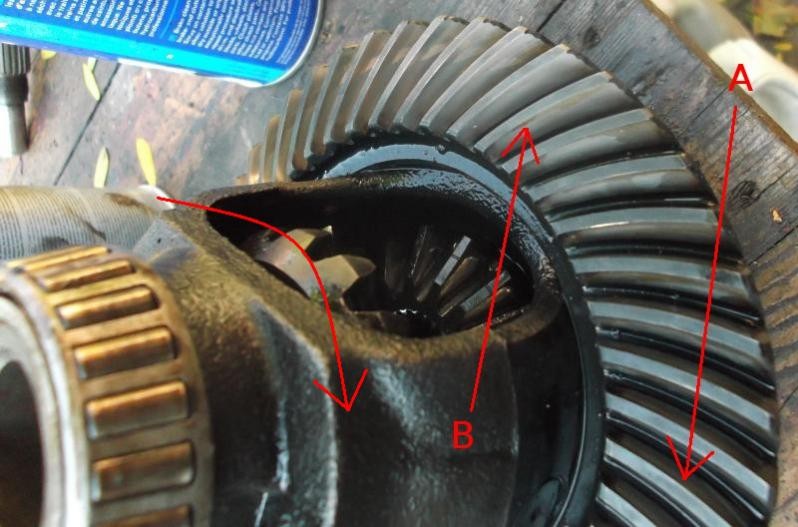

For the crown wheel in your Mercedes W201:

As illustrated above, the curved arrow indicates the direction of rotation during normal forward motion of your Mercedes-Benz W201. Arrow “A” points to the drive side of the tooth, while arrow “B” indicates the coast side.

Similarly, for the pinion gear:

Again, the curved arrow represents the forward rotation direction. Arrow “A” marks the drive side, and arrow “B” marks the coast side of the pinion gear tooth.

The interaction between these teeth necessitates a small gap, known as backlash. This clearance allows the gears to roll smoothly against each other. However, the pressure from this contact exerts force on the pinion, pushing it either towards or away from the crown wheel depending on whether the car is accelerating or decelerating.

During normal forward driving in your W201, the pinion is forced towards the larger tapered roller bearing, moving closer to the crown wheel. Conversely, in reverse, the pinion is pulled towards the smaller tapered roller bearing, away from the crown wheel. If the nut on the end of the pinion shaft isn’t correctly tightened, the pinion shaft will move back and forth every time you accelerate or decelerate. This shuttling motion puts undue stress on the tapered roller bearings.

These bearings require a specific pre-load to prevent this damaging movement. Proper pinion shaft preload is achieved by correctly tightening the pinion nut. Overtightening this nut results in excessive pre-load, which can shorten the lifespan of the bearings due to increased friction and heat. Conversely, undertightening the nut allows too much play, leading to the pinion shaft shuttling and causing impact damage and premature bearing failure.

In conclusion, ensuring correct pinion shaft friction, or preload, is a critical step in maintaining the differential of your Mercedes-Benz W201. Proper adjustment protects the longevity of the differential bearings and ensures the smooth and reliable operation of your classic Mercedes. Paying attention to this detail during any differential work will contribute significantly to the overall health and performance of your W201.