Understanding the detailed list of parts of an air compressor for car detailing is essential for any serious detailer. Whether you’re a seasoned professional or just starting out, knowing your compressor inside and out will allow you to troubleshoot issues, maintain it properly, and ultimately, get the most out of your investment. This knowledge translates to better performance and longer life for your equipment, saving you time and money in the long run.

Key Components of a Car Detailing Air Compressor

A car detailing air compressor isn’t just a single unit; it’s a system of interconnected parts working together to generate and deliver compressed air. Let’s break down the key components:

- Motor: The powerhouse of the system. It drives the pump and converts electrical energy into mechanical energy.

- Pump: This is the heart of the compressor. It draws in air and compresses it, increasing its pressure. Common types include piston and rotary screw pumps.

- Tank: The storage vessel for compressed air. Its size dictates how much air you can use before the compressor needs to cycle on again.

- Pressure Switch: This component regulates the pressure in the tank. It turns the motor on when the pressure drops below a set level and off when it reaches the desired pressure.

- Safety Valve: A crucial safety feature that releases excess pressure if the pressure switch fails, preventing damage to the tank and potential injury.

- Drains: Located at the bottom of the tank, these valves allow you to remove accumulated moisture, preventing rust and prolonging the life of your compressor.

- Gauges: These display the tank pressure and the regulated output pressure. They’re essential for monitoring performance and ensuring you’re using the correct pressure for your tools.

- Regulator: This controls the air pressure delivered to your tools. It allows you to adjust the pressure based on the specific needs of the task at hand.

- Hoses and Fittings: These connect the compressor to your air tools. Quality hoses and fittings are essential for preventing leaks and ensuring efficient airflow.

- Air Filter: This component prevents dust and debris from entering the pump, extending its lifespan and maintaining optimal performance.

Car Detailing Air Compressor Parts Diagram

Car Detailing Air Compressor Parts Diagram

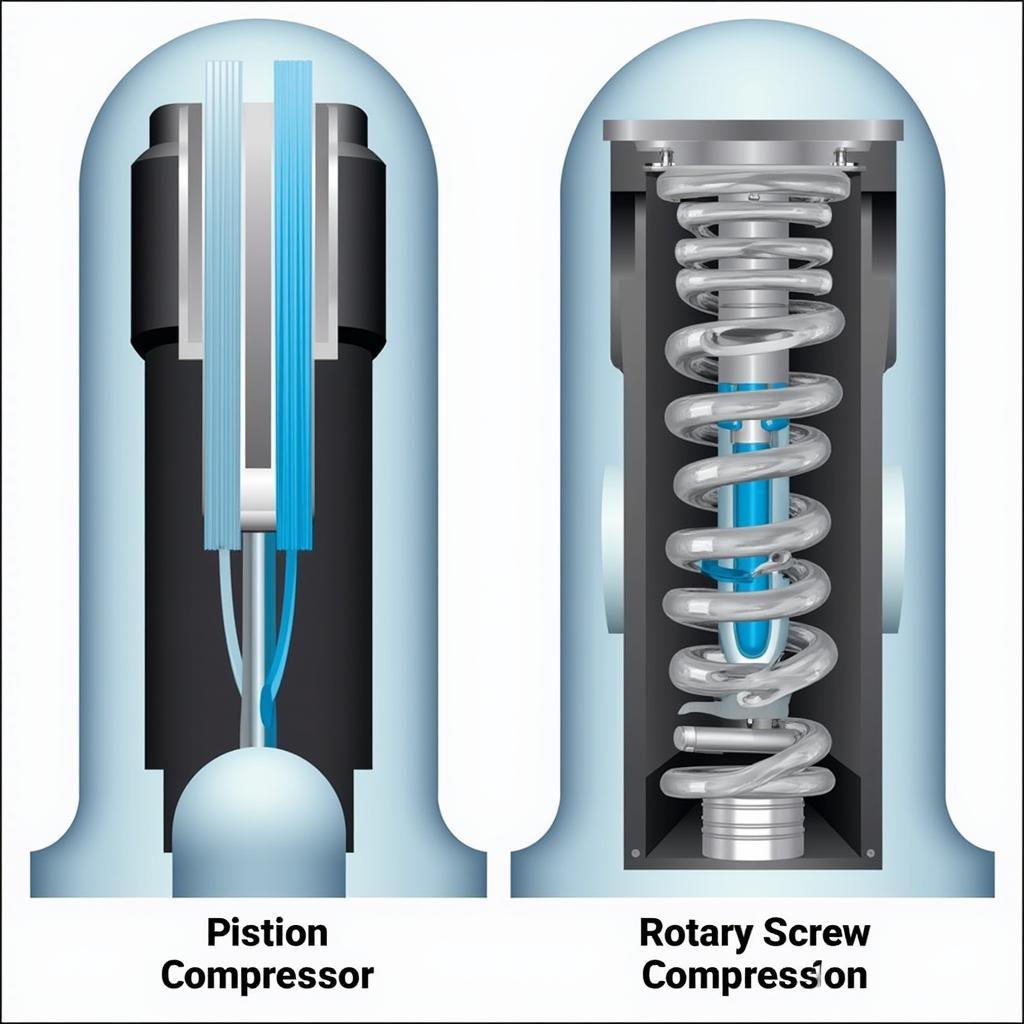

Understanding the Different Types of Air Compressor Pumps

There are two main types of pumps used in car detailing air compressors: piston and rotary screw. Understanding the differences between these two types is crucial for selecting the right compressor for your needs.

Piston Compressors

Piston compressors utilize a reciprocating piston within a cylinder to compress air. They are generally more affordable and suitable for intermittent use.

Rotary Screw Compressors

Rotary screw compressors utilize two rotating screws to compress air. They are more efficient, quieter, and better suited for continuous operation, making them ideal for high-volume detailing work.

Piston vs. Rotary Screw Compressor

Piston vs. Rotary Screw Compressor

Maintaining Your Air Compressor for Optimal Performance

Regular maintenance is essential for keeping your air compressor running smoothly and efficiently. Here’s a checklist of essential maintenance tasks:

- Drain the Tank: Drain the tank after each use to remove moisture.

- Check the Air Filter: Clean or replace the air filter regularly.

- Inspect Hoses and Fittings: Look for leaks and replace any damaged components.

- Check the Oil Level (for oil-lubricated compressors): Maintain the correct oil level.

- Test the Safety Valve: Ensure the safety valve is functioning correctly.

Air Compressor Maintenance Checklist

Air Compressor Maintenance Checklist

Conclusion

Knowing the Detail List Of Parts Of An Air Compressor For Car detailing is crucial for proper maintenance and optimal performance. By understanding the function of each component and implementing a regular maintenance schedule, you can ensure your compressor remains a reliable tool in your detailing arsenal. A well-maintained compressor translates to a more efficient workflow and ultimately, a better finish for your clients’ vehicles. So, invest the time to learn about your equipment – it will pay off in the long run.

FAQ

- How often should I drain my air compressor tank?

- What type of oil should I use in my air compressor?

- How do I know if my safety valve is working correctly?

- What are the signs of a failing air compressor pump?

- How do I choose the right size air compressor for car detailing?

- What is the difference between CFM and PSI?

- What are some common air compressor troubleshooting tips?

If you need further assistance, please contact us via WhatsApp: +1(641)206-8880 or Email: [email protected]. We have a 24/7 customer support team. You can also check out our tornado car detailing tool for efficient interior cleaning.

Leave a Reply