The 2019 Formula 1 season saw some of the most technologically advanced cars ever to grace the circuits. These machines are not just about raw power and speed; they are meticulously crafted masterpieces of engineering, pushing the boundaries of aerodynamics, materials science, and powertrain technology. Let’s delve into the fascinating world of 2019 F1 Car Details, exploring the innovations that made them so unique.

Aerodynamic Mastery: Sculpting Air for Performance

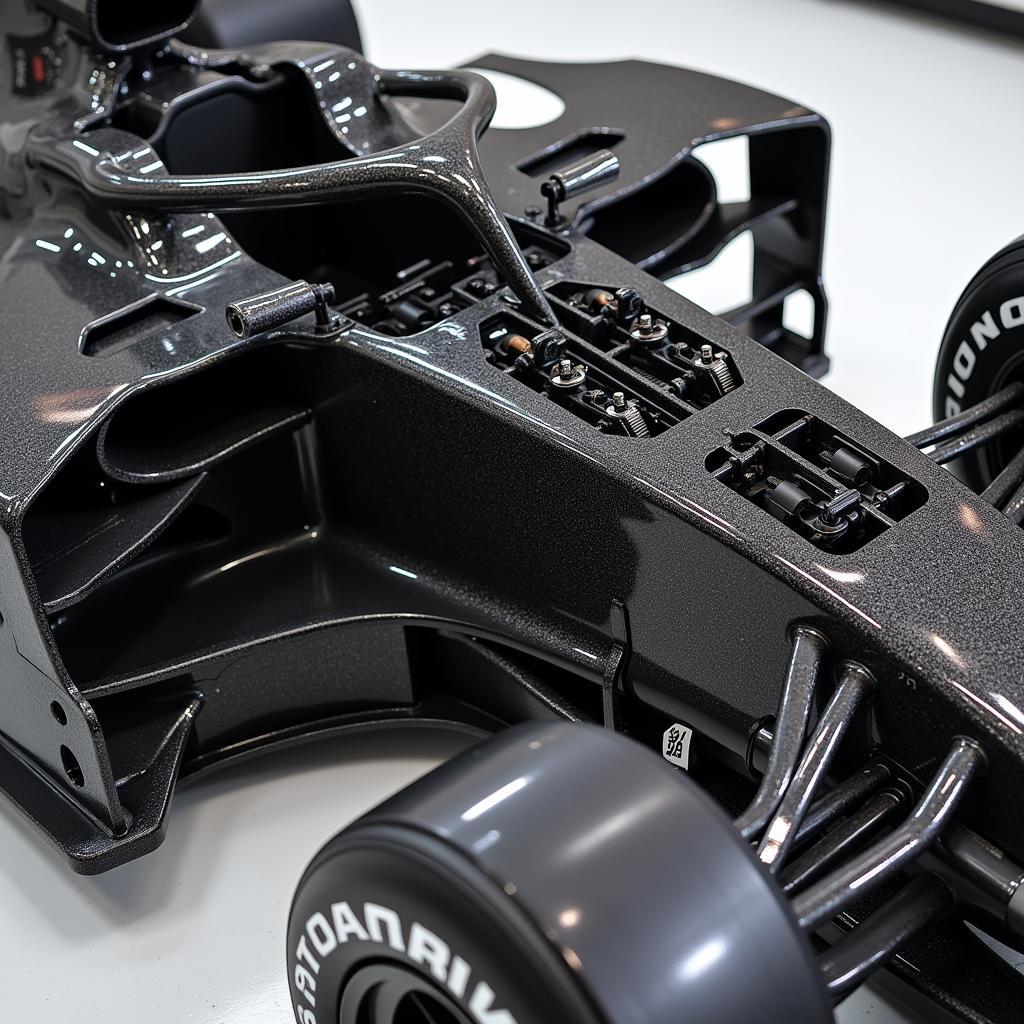

Aerodynamics plays a crucial role in F1, dictating a car’s speed, stability, and ultimately, its success on the track. The 2019 regulations brought about subtle yet significant changes to the aerodynamic regulations, leading to a renewed focus on front-wing design. Teams experimented with intricate multi-element front wings, featuring an array of winglets, turning vanes, and carefully sculpted endplates. These elements work in harmony to manage the airflow around the car, generating downforce for increased grip and cornering speeds.

Beyond the front wing, the 2019 F1 cars featured complex bargeboards, sidepods, and rear wings, all designed to optimize airflow and minimize drag. The diffuser, located at the rear of the car, played a crucial role in extracting downforce by creating a low-pressure area beneath the car. Teams invested countless hours in wind tunnels and computational fluid dynamics (CFD) simulations to fine-tune their aerodynamic packages, seeking that marginal advantage over their rivals.

Powertrain Prowess: Hybrid Synergy for Efficiency and Performance

2019 F1 car engine with hybrid powertrain components

2019 F1 car engine with hybrid powertrain components

The 2019 F1 cars continued to utilize the 1.6-liter turbocharged V6 hybrid power units introduced in 2014. These powertrains are a testament to engineering ingenuity, combining a powerful internal combustion engine with sophisticated energy recovery systems.

The hybrid element comprises two motor generator units: the MGU-K, which recovers kinetic energy from braking, and the MGU-H, which harvests energy from the turbocharger. This recovered energy is stored in a battery and can be deployed strategically to boost power and improve fuel efficiency.

“The 2019 power units were incredibly sophisticated,” explains former F1 engineer, Mark Thompson. “Teams were constantly refining their energy management strategies to extract maximum performance within the fuel flow limits.”

Lightweight Construction: Carbon Fiber and Advanced Materials

2019 F1 car monocoque chassis made of carbon fiber

2019 F1 car monocoque chassis made of carbon fiber

Weight is the enemy of speed, and F1 teams are obsessed with shedding every possible gram from their cars. The 2019 F1 cars extensively utilized lightweight materials, with carbon fiber being the material of choice for the chassis, bodywork, and many internal components.

Carbon fiber offers an exceptional strength-to-weight ratio, making it ideal for creating a rigid yet lightweight structure. Teams employed advanced manufacturing techniques, such as autoclave curing and pre-preg layup, to create intricate carbon fiber components with incredible precision.

Beyond carbon fiber, teams explored other lightweight materials, including titanium alloys for exhaust systems and magnesium alloys for gearbox casings, all in the relentless pursuit of minimizing weight and maximizing performance.

Conclusion

The 2019 F1 cars were rolling showcases of cutting-edge technology, demonstrating the pinnacle of motorsport engineering. From their sculpted aerodynamic surfaces to their powerful hybrid powertrains and lightweight construction, every detail was meticulously crafted to achieve the ultimate goal: speed. These cars serve as a testament to the relentless pursuit of innovation and excellence that defines the world of Formula 1.

Leave a Reply